Quatro SPH 400

Compact and portable, the SPH 400 Fume Extractor series is designed for heavy duty laser applications.

SHOP SPH 400

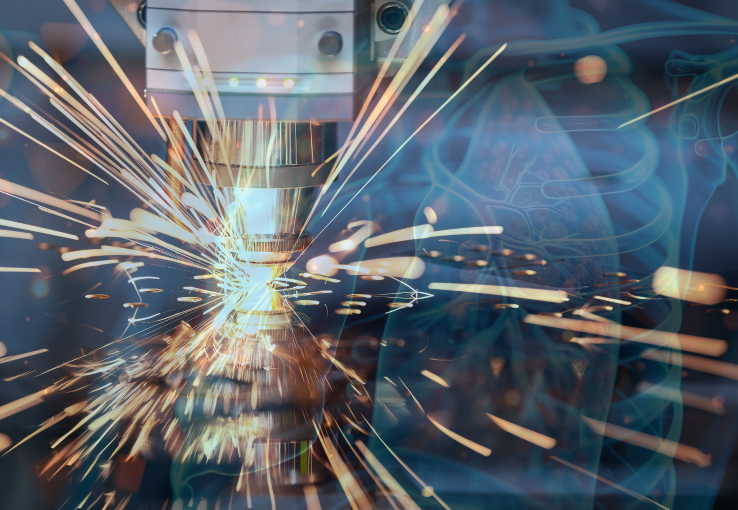

Laser engraving and laser etching, two forms of laser cutting, provide a quick and precise way to produce permanent marks on a variety of solid substrates like wood, rigid plastics, glass, and metal. However, when the high powered lasers that are used in these machines burn away thin layers of material, they generate microscopic particles and gaseous fumes which can be hazardous and even toxic to respiratory health when not properly managed.

To reduce the risks associated with laser generated fumes and process dust, Diversitech presents advanced air filtration solutions equipped with high-efficiency systems and easy-to-use technology that can be implemented in community maker spaces, wood working, jewelry making, and more. We also offer heavy-duty filtration devices for demanding industrial applications such as automotive, aerospace, electronics, dental, and medical manufacturing. Explore our selection of fume extractors and dust collectors for laser engraving machines below.

The fumes and particles that are associated with laser cutting operations are called Laser-Generated Air Contaminants or LGACs. The exact contents of LGACs will vary depending on the type of laser used, the intensity of the laser, the target substrate material, and other factors; but generally these contaminants include different forms of particulate matter, volatile organic compounds (VOCs), hexavalent chromium, and other types of unbreathable, airborne matter. Repeated or prolonged exposure to LGACs can lead to a wide variety of short term discomfort and chronic respiratory conditions including:

Contact Diversitech today for expert advice tailored to your needs.

GET STARTED

We offer 2 different motor types suited for different work capacities:

Filter bags are recommended due to the materials you are working with. Any material high in glue/resin or adhesives such as wood or cardboards tend to consume filters quickly. The glues are vaporized when heated and then they condense onto the filters blocking them. Bag filters are added as an extra level of filtration in order to handle most of this sticky fume load and further to prolong the life of HEPA filters (HEPA filters are much more expensive). The filter bags will not necessarily fill up – they get coated with “sticky fume particulate”. On the SPH400/SPH800 series, the pre-filter section is an additional section that can be added on in the field at a later date if you feel it is necessary. The same result will occur with any filtration system as your application creates this type of fume.

It depends on the materials you are working with, how deep you are cutting / engraving, the laser wattage and how often the laser is being used. Typical applications have the pre-filter being changed approximately every 1-3 months, HEPA filter 6-12 months, chemical filter 6-12 months. This is just a guide as some parameters lead to filters lasting much longer, while others consume the filters much more quickly.

LaserBlue Gel, which can be found inside of QUATRO laser engraver fume extractors, is a seal that forms an impenetrable barrier against hazardous fumes, odors, and VOCs generated through laser cutting and marking processes. The chemical filter within each QUATRO unit is sealed with LaserBlue Gel, which guarantees zero filter bypass and 100% initial filtration efficiency. This makes it safe to recirculate filtered air in your workplace.

Quatro SPH fume extractors are compatible with most major laser brands, including:

… and many more. For more information about laser compatibility with our fume extraction systems, contact us.